| |  | |  |

| I believe the first step for prepping an engine for the race car is to make sure the oilpan can be secured time after time to the engine without concern. This means helicoils for front and rear of engine. | | For the 6mm bolts, a 1/4 inch drill is used, and of course the supplied tap with the 6mm helicoil kit. Obviously keep debris from getting into engine. | | I used the 1/4 inch bit last of three graduated sizes leading up to that size. Probably overkill, but keeps it clean. |

|

| |  | |  |

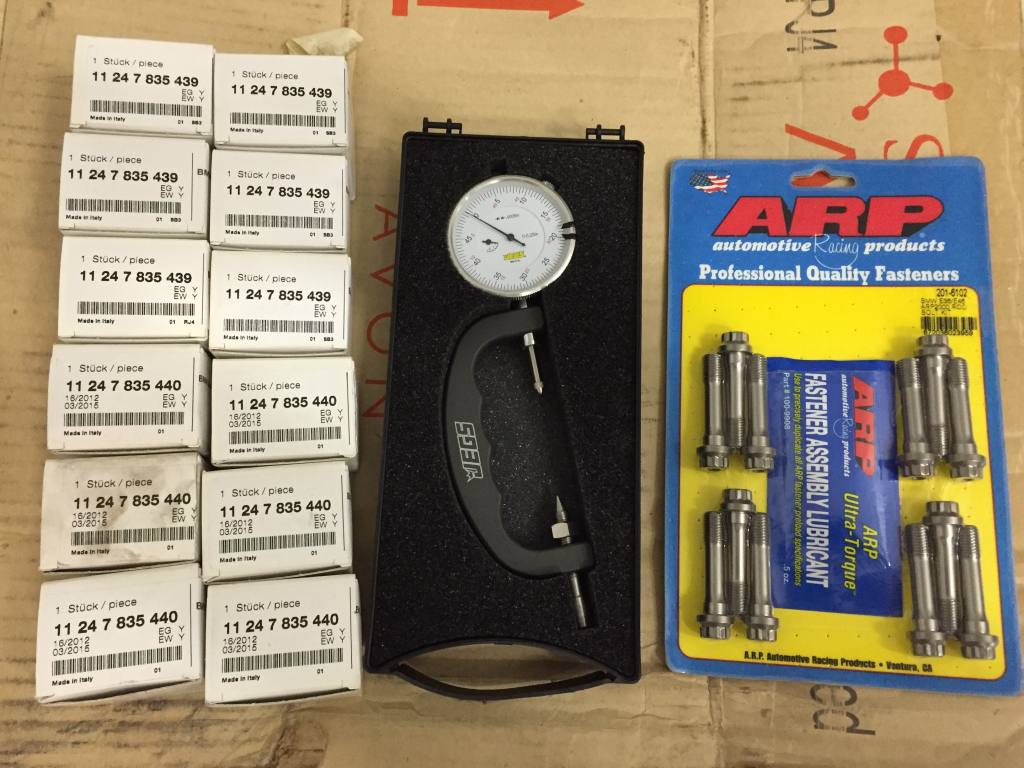

| I found that one can use the M6 x 1.00 x 12mm size for all of the six bolts on the two covers. | | Done. There is nothing worse than buttoning up an engine, and putting in that last bolt, and finding that it strips. This takes care of that issue, and is quick and easy. | | Next step is putting in a fresh set of Bearings, and using a Stretch Guage to put the ARP bolts in properly. |

|

| | | | |

| JEG's makes a Stretch gauge, but it won't support its weight if held vertically. I added washers and a spring to convert this gauge to something usefull. Used two #10 washers, one #4 washer, and a 29/32 x 3/8 x .032 Compression Spring. May cut down a longer, smaller diameter one, and get rid of the #10 washers so it looks nicer. Works now. | | | | |

|